Overview: Packaging Tools in Logistics

Material Composition and Application Techniques

Strength and Load Retention Comparison

Speed and Cost of Application

Use Cases and Flexibility in Packaging Lines

Environmental and Storage Considerations

Feedback from High-Volume Warehousing Operations

Safety and Ergonomic Factors

Supplier Selection Criteria and Customization

Final Thoughts: Choosing the Best Fit for Your Operation

In today’s competitive logistics landscape, companies are constantly evaluating tools to maximize efficiency and reduce operational risks. Two of the most debated solutions for securing loads are filament reinforced tape and traditional strapping. Bulk buyers working with a filament tape manufacturer often weigh cost, ease of use, and material durability when making decisions.

While both offer high tensile performance, filament reinforced tape wholesalers have introduced advanced cross-woven designs that can rival traditional strapping in certain scenarios. The growing adoption of quality filament tapes in export, warehousing, and e-commerce fulfillment reflects a shift in preferences across many industries.

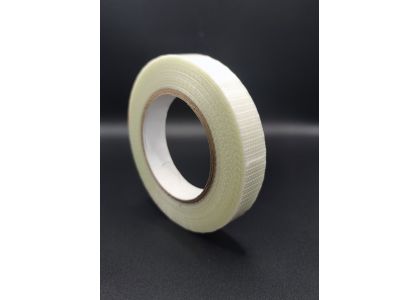

Strapping is typically made from polypropylene (PP), polyester (PET), or steel. It's applied using tensioners and sealers, often requiring specialized machinery. Filament reinforced tape, in contrast, incorporates fiberglass or polyester strands within an adhesive base, allowing for hand or dispenser-based application without heat or mechanical clamps.

The result? Faster, simpler deployment on diverse packaging lines. According to a filament tape manufacturer, this difference is especially appreciated in manual packaging environments or smaller warehouses that lack automation budgets.

Traditional strapping holds an edge in very heavy-duty applications—such as securing industrial machinery to pallets. However, filament reinforced tape offers excellent tension stability and tear resistance for 80% of typical packaging needs.

Quality filament tapes from certified filament reinforced tape wholesalers now support up to 600 lbs per inch of width. Their layered construction also reduces edge cutting into cartons, offering a more forgiving load surface that preserves outer packaging.

Applying strapping involves multi-step procedures, including tensioning, sealing, and tool maintenance. This slows down packing line speed and increases labor costs.

On the other hand, filament reinforced tape requires minimal training and integrates smoothly into both automated and manual lines. A study conducted at a Dongguan electronics export center revealed that switching to quality filament tapes improved pack-out time by 22% while lowering material handling incidents.

Filament reinforced tape wholesalers report strong demand from sectors like:

Consumer electronics

Pharmaceuticals

Apparel and soft goods

Lightweight appliances

While strapping is still favored for bundling metal tubes or bricks, filament tape manufacturers see increased use in applications requiring speed and low abrasiveness. It also accommodates variable load shapes better than rigid strapping lines.

Strapping reels are bulky and can degrade under UV light or moisture. Filament reinforced tape, in contrast, stores compactly and maintains adhesive properties across a broader range of temperatures.

Sustainability-wise, quality filament tapes are now being offered with partially recycled backings, making them more appealing to eco-conscious brands. Some filament reinforced tape wholesalers even offer carbon footprint tracking for export-grade lots.

At a major Shanghai fulfillment hub, operations managers reported fewer tape failures when transitioning from traditional strapping to filament reinforced tape. They noted better workflow integration, faster training, and higher worker satisfaction.

One warehouse supervisor stated: “With strapping, our team needed 3 people per station. With filament tape, 1 person can do the same job faster and safer.”

Strapping tools can pose injury risks, including cuts and repetitive strain. Filament tape manufacturers emphasize the ergonomic advantages of tape—it’s lighter, easier to unwind, and reduces strain on wrists.

For companies prioritizing workplace safety and ergonomics, quality filament tapes present a clear advantage, particularly in environments with high packaging volume and staff turnover.

Working with a reputable filament reinforced tape wholesaler is essential for consistency. Consider these when selecting a supplier:

Tensile strength rating options

Adhesive customization

Availability of printed logos or barcodes

Compliance with export certifications

Reliable filament tape manufacturers also provide on-site testing samples and engineering support to integrate new materials into legacy systems.

Both strapping and filament reinforced tape offer unique benefits. For operations requiring high precision, ergonomic safety, and application speed, partnering with a trusted filament reinforced tape wholesaler may be the most effective route.

As packaging demands evolve, flexibility, safety, and sustainability will continue to shape material preferences across industries. And quality filament tapes, particularly those from innovation-driven filament tape manufacturers, are set to play an increasingly central role.