Powder coating processes require masking materials that can withstand oven temperatures often exceeding 400°F (204°C). While high temp tape and heatproof adhesive tape are designed for such conditions, many still consider using inexpensive regular masking tape. This article evaluates the suitability of standard masking tape for powder coating and guides you through selecting the best powder coating masking tape, incorporating green taping practices and procurement insights.

Powder coating involves applying a dry resin powder to metal surfaces, then curing in a high‑heat oven to create a durable finish. Effective masking tape must meet four critical criteria:

Temperature Resistance: Tape must hold at curing temperatures (204–260°C) without melting or lifting.

Adhesive Strength: A robust bond prevents powder seepage under edges.

Clean Removal: Post‑cure, the tape should peel away with no residue.

Chemical Resistance: Tape must resist chemicals, solvents, and cleaning fluids used before or after curing.

Standard masking tape, typically made from paper and basic pressure‑sensitive adhesive, often fails one or more of these requirements under powder coating conditions.

| Issue | Impact on Powder Coating |

|---|---|

| Low Temperature Tolerance | Adhesive softens, tape deforms and peels |

| Adhesive Residue | Sticky build‑up leading to coating defects |

| Poor Conformability | Gaps on curved or detailed surfaces |

| Structural Weakness | Splitting under heat, uneven edges |

Regular masking tape risks lifting during cure and contaminating the finish, resulting in messy edges and costly rework.

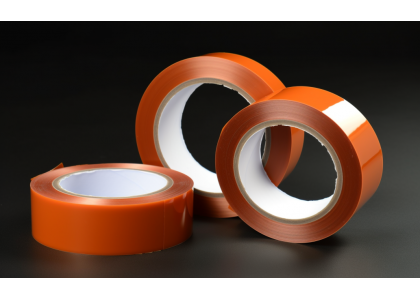

When sourcing powder coating tape supplies, prioritize these specialized options:

Powder Coating High Temp Tape: Rated up to 500°F (260°C), designed specifically for powder coating lines.

Polyester (PET) Tape: Balances cost and performance for general‑purpose masking.

Polyimide (Kapton) Tape: Exceptional kapton tape temperature resistance, ideal for fine‑line and high‑heat applications.

Silicone Adhesive Tape: Superior adhesion and clean removal, even after prolonged high‑heat exposure.

Application Case: An automotive parts manufacturer switched from regular crepe tape to heatproof adhesive tape, reducing edge defects by 85% and cutting rework time by two days per lot.

| Tape Type | Max Temp | Adhesive | Residue Risk | Best Use |

| Powder Coating High Temp | 500°F | Acrylic | Low | Industrial powder coating lines |

| Polyester (PET) Masking | 400°F | Rubber | Medium | Standard powder coating |

| Polyimide (Kapton) Masking | 500°F+ | Silicone | Very Low | Precision masking, circuits |

| Silicone Masking Tape | 500°F | High‑temp Sil | Minimal | Critical surfaces, tight curves |

Before ordering, confirm your supplier offers:

Technical Data Sheets (TDS): Including temperature rating and adhesive specs.

Sample Rolls: Test on your oven and substrate to verify performance.

MOQ and Lead Time: Ensure production schedules align with your curing cycles.

Certifications: ISO 9001, RoHS, UL compliance for industrial use.

Bulk Pricing & Support: Discounts, technical guidance, and reliable powder coating tape supplies.

Q1: Can I use high temp tape instead of powder coating tape?

Only use tapes labeled for powder coating; general high-temp tapes may lack the clean‑remove formula.

Q2: What is green taping?

Implementing eco‑friendly tapes with recyclable backings and low‑VOC adhesives to reduce environmental impact.

Q3: How important is adhesive residue?

Residue compromises powder adhesion; always choose low‑residue, high‑temperature adhesives.

Q4: Where to buy heatproof adhesive tape in bulk?

Look for specialized industrial suppliers offering volume discounts and technical support.

Adopt green taping by selecting tapes with recycled backings or water‑based adhesives. Route used masking strips for recycling when possible, and work with suppliers to minimize packaging waste. Sustainable masking not only reduces your carbon footprint but also supports corporate social responsibility goals.

Regular masking tape is inadvisable for powder coating due to inadequate heat and adhesive performance. By selecting specialized high temp tape, heatproof adhesive tape, or polyimide masking tape, and following our procurement checklist, you’ll achieve clean, durable results—while embracing green taping strategies for an eco-friendly operation.