In modern manufacturing and surface treatment processes, powder coating masking tape has become an indispensable tool. As industries demand higher precision, durability, and eco-friendly solutions, especially under extreme conditions, high temperature tape applications require customized specifications. Whether you need high temp tape for automotive painting, aerospace component coating, electronics encapsulation, or premium furniture finishes, custom-tailored powder coat masking solutions can dramatically improve efficiency and quality.

Standard masking tapes are designed for general applications, but face multiple challenges in specialized environments:

Inadequate Heat Resistance: Off-the-shelf tapes may soften, degrade, or leave residue when exposed to curing temperatures above 150°C, leading to coating defects and extra cleaning time.

Poor Conformability: Complex shapes, sharp corners, and textured surfaces can cause gaps, leading to coating bleed and uneven coverage.

Low Peel Strength: Too-strong adhesives can tear substrate materials, while weak bonds allow coatings to seep beneath the tape edges.

Uncontrolled Widths and Thicknesses: Manual trimming of wide tapes wastes material and slows down production lines.

Environmental Concerns: Many tapes rely on solvent-based adhesives and non-recyclable backings, conflicting with green manufacturing goals.

These limitations underscore the importance of customized powder coating tape solutions tailored to specific operational requirements.

By customizing powder coating masking tape parameters—adhesive formula, backing material, thickness, and color—manufacturers can unlock the following benefits:

Optimal Thermal Performance: Custom high-temperature tape withstands curing cycles up to 240°C (464°F) or higher, ensuring dimensional stability and residue-free removal even after prolonged exposure.

Tailored Adhesion: Adjusting silicone or acrylic adhesive concentrations allows precise control over peel strength, minimizing substrate damage and residue while ensuring secure bonding throughout the process.

Precision Dimensioning: Millimeter-accurate widths and calibrated thicknesses (50–150 µm) eliminate the need for on-site trimming, reduce waste, and streamline automated tape application systems.

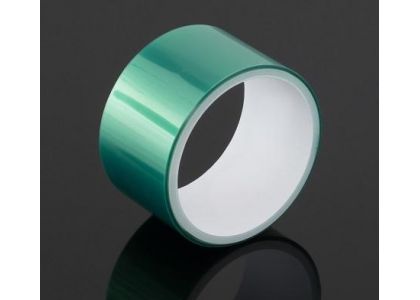

Enhanced Conformability: Specialized backings—PET, polyimide, or flexible cloth—enable green taping efforts on curved, textured, or intricate surfaces without compromising masking accuracy.

Color-Coded Identification: Bright green, red, blue, or custom-printed tapes facilitate process tracking, quality control checks, and safety compliance.

Eco-Friendly Materials: Water-based silicone adhesives and recyclable PET backings align with environmental regulations, supporting corporate sustainability commitments.

When evaluating powder coating masking tape suppliers, consider the following key specifications:

|

Parameter |

Definition |

Customization Range |

|

Temperature Rating |

Max continuous/peak cure temperature |

180–260°C(356–500°F) |

|

Peel Adhesion |

Force needed to remove tape cleanly (N/25 mm) |

0.8–4.0 N |

|

Backing Thickness |

Total tape thickness (µm) |

50–150 µm |

|

Adhesive Type |

Silicone, acrylic, rubber |

Silicone for high-temp, acrylic for general use |

|

Backing Material |

PET, polyimide, cloth |

PET for cost-efficiencyPolyimide for extreme heat |

|

Width Tolerance |

Custom die-cut precision (mm) |

±0.2 mm |

|

Color & Printing |

Solid or printed logos/text |

Any Pantone color |

Thorough testing under actual process conditions ensures the selected high temp tape meets your performance targets.

Challenge: Achieve precise body panel masking during electrostatic powder application and oven curing at 200°C.

Solution: Customized 75 µm PET-backed tape with a medium-silicone adhesive.

Result: 35% reduction in edge bleeds and 20% faster line speed due to easy peel-off and no residual cleanup.

Challenge: Multi-layer coatings on turbine blades require tapes that can endure 230°C without delamination.

Solution: Polyimide-based powder coat masking tape with ultra-high-temperature silicone adhesive.

Result: Zero tape failures across 10,000+ blade assemblies; 15% decrease in rework cycles.

Challenge: Masking electronic enclosures during conformal coating and cure processes up to 150°C.

Solution: Thin (50 µm) acrylic adhesive tape for no-curl, zero-bleed performance.

Result: 99.8% yield rate on PCB conformal coatings; reduced material handling time by 25%.

Challenge: Repeated oven cycles at 220°C for spray booths and conveyor systems.

Solution: 100 µm cloth-backed tape with robust silicone adhesive for heavy ink and powder loads.

Result: Extended maintenance intervals by 40%; masked area cleaned effortlessly after 50 cycles.

Challenge: Blend aesthetics with precision masking on metal frames under 180°C powder finishes.

Solution: Custom green taping PET tape with printed QR codes for work-in-progress tracking.

Result: 30% faster setup times; streamlined QC checks via QR code scanning.

A leading electric vehicle manufacturer launched a green taping initiative to reduce solvent use and recycling burdens. Working with our R&D team, they implemented water-based silicone adhesives on PET backings, maintaining a 210°C cure cycle without residue. The pilot project:

Cut VOC emissions by 60% through solvent-free adhesive systems.

Achieved a 25% cost reduction in tape procurement due to backing recyclability.

Attained customer satisfaction scores above 95% for surface quality.

This initiative exemplifies how powder coat masking innovation can align with sustainability goals while enhancing production metrics.

Requirement Analysis: Collaborative engineering sessions to define process temperatures, substrate materials, and masking complexity.

Prototype Development: Small-batch runs for performance validation on customer equipment.

Scalable Production: High-precision coating lines ensure consistent high temp tape quality across large volumes.

Post-Installation Support: Onsite trials, quality audits, and iterative refinements based on real-time feedback.

In today’s competitive landscape, generic tapes can hamper production efficiency and quality. By investing in customized powder coating masking tape, companies gain unmatched precision, cost savings, and environmental benefits. Collaborate with a specialized powder coating tape supplier to unlock new performance levels and achieve your production goals seamlessly.