In the fast-paced world of electronics manufacturing, Surface Mount Technology (SMT) requires precision, particularly when it comes to managing temperature during soldering. Protecting sensitive components from thermal damage is critical, and materials like polyimide tape 3D printing have become integral to achieving consistent performance. Leading polyimide tape producer companies offer innovative solutions with carefully engineered polyimide tape thickness, impressive polyimide tape max temperature ratings, and stable adhesion. These attributes allow manufacturers to maintain assembly quality while optimizing operational efficiency—highlighting the value of sourcing from a reputable polyimide tape company.

SMT processes rely on components and materials that can withstand the extreme heat cycles inherent to soldering operations. Polyimide tape manufactured using advanced 3D printing techniques has demonstrated outstanding thermal stability, making it particularly suitable for demanding electronic applications. Its heat-resistant properties allow it to remain intact throughout various stages of soldering, protecting critical parts from warping or failure. With a high polyimide tape max temperature threshold, this type of tape ensures components are safeguarded against prolonged exposure to heat.

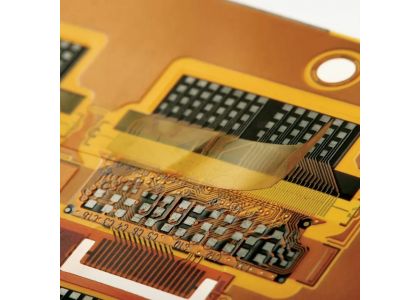

One of the defining factors in SMT tape selection is the consistency of polyimide tape thickness. Uniform thickness across all batches helps manufacturers avoid performance variability, ensuring each solder joint receives the same level of thermal protection. Leading polyimide tape producer companies have invested in precision manufacturing technologies to deliver products that meet tight tolerances. Additionally, the adhesive systems used in high-performance polyimide tapes are formulated to maintain their bond strength even when exposed to repeated temperature cycles, further contributing to the stability and reliability of SMT assemblies.

Incorporating polyimide tape 3D printing into the assembly line enables more effective thermal management across the board. Not only does the tape act as a barrier against excess heat, but it also helps distribute thermal energy more evenly, preventing localized overheating. When combined with optimized polyimide tape thickness, this material enhances the integrity of solder joints and minimizes the risk of thermal stress cracking. These performance advantages translate to higher throughput and fewer defects during production.

Manufacturers across the electronics sector have seen tangible benefits from adopting next-generation polyimide solutions. One international assembler reported that integrating a new series of polyimide tape developed through 3D printing led to a noticeable reduction in soldering defects. Technicians attributed these improvements to the material’s thermal resilience and consistent application thickness. Another notable benefit was the tape’s ability to adhere reliably, which was especially valuable during high-speed, high-volume production runs. Sourcing from a proven polyimide tape company ensures access to products that meet strict quality benchmarks and support scalable operations.

To maximize the advantages of polyimide tape, it is essential to follow best practices during application. Thorough surface preparation of PCBs, including cleaning and degreasing, ensures optimal adhesion. Applying the tape with calibrated equipment ensures uniform coverage and maintains the correct polyimide tape thickness for thermal protection. Periodic inspections and quality checks throughout the soldering process help confirm that the tape remains in position and continues to provide effective insulation.

The use of thermally stable polyimide tapes offers a clear return on investment. Reduced rates of rework and improved first-pass yield contribute directly to lower production costs. The high polyimide tape max temperature capability means fewer interruptions during manufacturing due to tape failure, resulting in consistent process uptime. These operational benefits, coupled with improved product reliability, make advanced polyimide tapes an ideal choice for companies aiming to enhance profitability without compromising on quality.

As SMT technology continues to evolve, future developments in polyimide tape are expected to focus on increased functionality. Innovations may include ultra-thin profiles that maintain high heat resistance, or intelligent tapes that adapt in real time to temperature fluctuations. Companies that work closely with established polyimide tape producer brands are more likely to gain early access to these breakthroughs. The ongoing collaboration between tape manufacturers and SMT specialists is set to drive continued improvement in thermal management practices across the electronics industry.