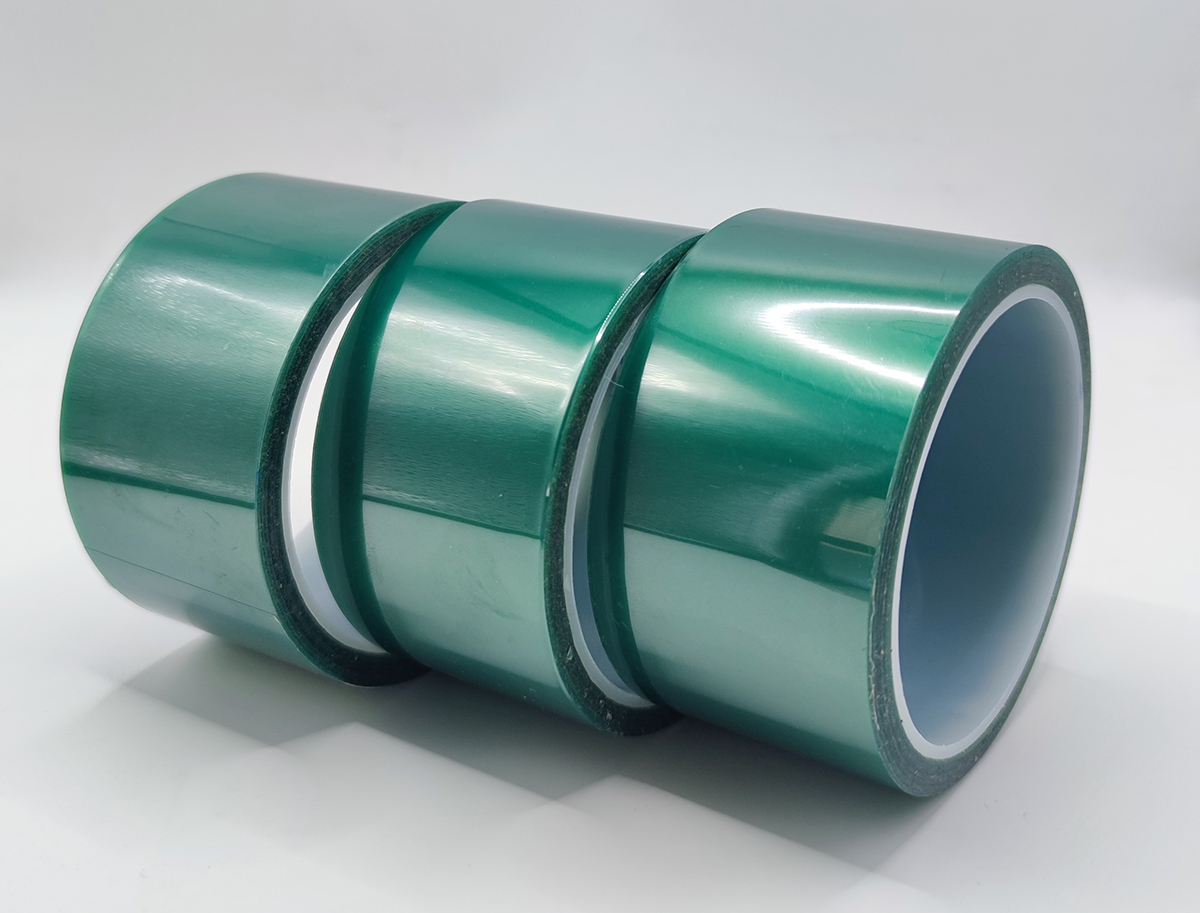

Choosing the right premium quality powder coating tape is more than a matter of price or color—it’s about ensuring your masking tape can endure the curing process without adhesive breakdown, smearing, or post-bake residue. Temperature rating plays a pivotal role in determining how the tape performs under heat exposure, especially in high-volume industrial ovens. Many professionals buy powder coating tape based on maximum temperature claims without fully evaluating the match between tape specs and their coating line’s actual conditions. The best Powder Coating Masking Tape options balance high-temperature tolerance, ease of removal, and clean finish lines—especially for users applying polyester, epoxy, or hybrid powders. When end-users buy Green polyester tape, they often overlook performance variances across tape categories, which can lead to costly rework or failed batches.

Properties: Typically feature PET backings with rubber or acrylic adhesives, priced for general-purpose masking. Temperature rating up to 200 °C (392 °F) makes them suitable for light powder coat cycles and baked finishes under moderate heat. These tapes offer ease of application, decent conformability, and clean removal when used within their limits.

Example: tesa® 50620 Basic powder coating tape handles up to 200 °C for 30 minutes, offers hand-tearable PET backing, and removes cleanly without residue. When you buy powder coating tape rated to 200 °C, expect easy application and removal but limited protection in more demanding bake cycles.

Usage Tip: For aluminum bike frames or steel brackets cured at lower temperatures, these entry-level options are cost-effective. However, applying them to oversized or heat-retaining parts can push them beyond tolerance and cause adhesive bleed.

Properties: Often silicone-adhesive polyester tapes rated to 204–260 °C, balancing cost and temperature resilience. They maintain dimensional stability, resist chemical exposure, and leave sharp masking lines. These are the workhorses of the industry, offering solid reliability for automotive, general metal finishing, and electrical enclosures.

Example: 3M™ Polyester Tape 8991 performs from –50 °C to 204 °C (400 °F) and excels in demanding anodizing and powder coat masking tasks. For operations requiring consistent results at moderate-high temperatures, using the best Powder Coating Masking Tape in this range reduces defects and post-process cleanup. Many finishers prefer to buy Green polyester tape in this category for its superior resilience during extended bake cycles.

Industry Insight: In electronics or appliance manufacturing, where oven dwell time varies, mid-range tapes offer sufficient thermal tolerance without the expense of high-performance options.

Properties: Utilize polyimide or advanced silicone adhesives capable of withstanding extreme bake cycles up to 260–371 °C. These tapes resist continuous exposure to 260 °C (500 °F) and brief spikes to 371 °C (700 °F), making them ideal for specialized aerospace or heavy-duty automotive finishes. They also perform well in harsh chemical washdowns post-bake.

Example: MOCAP High-Temperature Polyimide Tape endures 260 °C for one hour and brief exposures up to 371 °C, with clean removal and no adhesive residue. Customers who buy Green polyester tape for extreme-heat applications often switch to polyimide backings when peak cure temperatures exceed 260 °C.

Note on Costs: These tapes are more expensive due to the material and adhesive technology involved. However, their reliability in critical operations often results in overall cost savings by reducing failures.

Tapes for powder coating aren’t just about temperature—surface chemistry matters too. Certain metals like aluminum oxidize easily, affecting adhesion. For these cases, premium quality powder coating tape designed for clean release on non-ferrous metals is essential. If you buy powder coating tape for mixed-material parts or treated surfaces, prioritize tapes with adaptive adhesives.

In mixed-material assemblies, where aluminum and steel are present, dual-performance tapes or hybrid adhesive systems provide a bridge. Specialty silicone-based tapes maintain adhesion even with pre-treatment chemicals.

A large automotive supplier transitioned from a 200 °C tape to a silicone-adhesive 204 °C polyester tape after encountering edge-bleed at higher oven temperatures. The switch to premium quality powder coating tape rated at 204 °C eliminated masking failures, cut rework by 18%, and saved 12% in material costs over six months. When their process later upgraded to specialty high-gloss finishes requiring 230 °C cures, they evaluated both 3M™ 8991 and tesa® 50620; ultimately, the best Powder Coating Masking Tape designation went to the 3M product for its wider temperature margin and superior adhesion consistency. Today, they exclusively buy Green polyester tape for its consistency across seasonal ambient temperature changes.

Over-Reliance on Manufacturer Specs: Ratings often reflect lab-controlled environments. Field conditions can vary, especially with inconsistent curing ovens.

Ignoring Peel Temperature: Removal at incorrect substrate temperatures can cause adhesive transfer even if the tape’s temperature rating is suitable.

Improper Storage: Tapes stored in humid or high-temperature warehouses may degrade before use, reducing their effective temperature tolerance.

Feedback from one electronics firm using custom steel chassis revealed that switching to the best Powder Coating Masking Tape for high temp but storing it poorly led to unexpected delamination. Proper storage revived the tape's performance, proving that handling is as critical as selection. Others in the industry who regularly buy powder coating tape now emphasize climate-controlled tape storage as standard operating procedure.

Match Rating to Process: Always choose a tape rated at or slightly above your maximum bake temperature to avoid adhesive failure.

Consider Adhesive Type: Silicone adhesives outperform rubber or acrylic in high-heat and chemical-exposure environments.

Balance Cost vs. Performance: Entry-level tapes save upfront costs but may incur higher rework; high-performance tapes cost more but reduce defects in extreme-heat operations.

Evaluate Backing Material: PET backings offer good rigidity and cost efficiency; polyimide backings provide unmatched thermal endurance when cure temperatures exceed 260 °C.

Factor in Handling Practices: Ensure proper tape storage and removal technique to preserve adhesive performance.