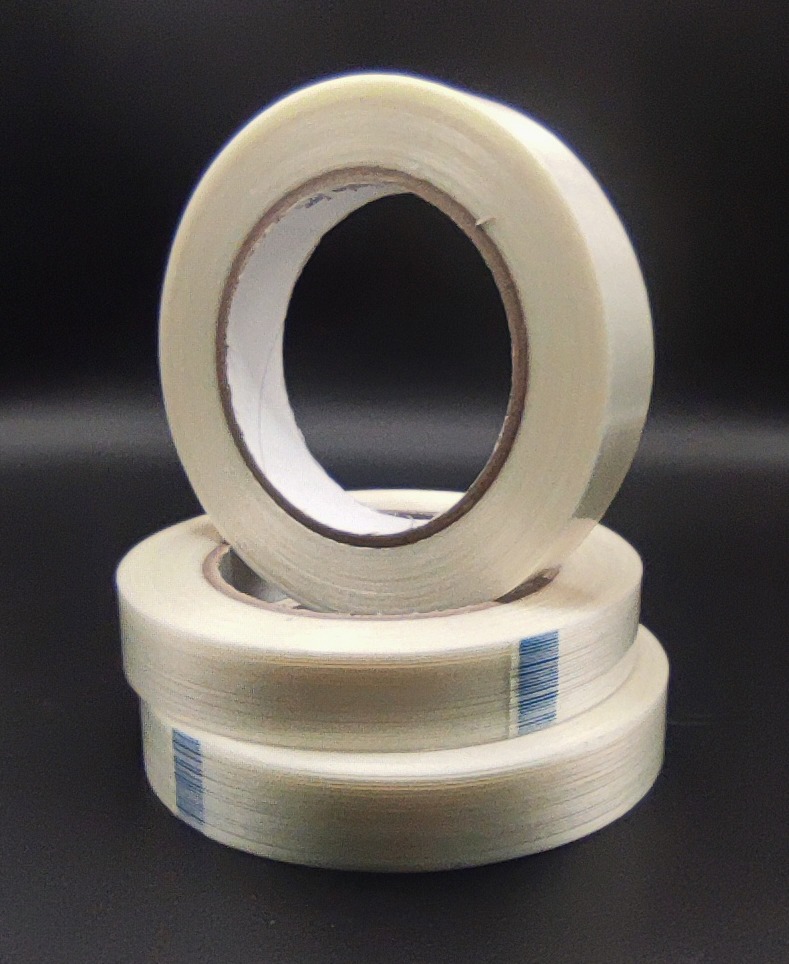

Filament electrical tape is widely known for its excellent insulation properties, but its versatility stretches far beyond basic protection. In modern power transformer design, engineers and manufacturers are finding new ways to leverage this durable material. This guide explores five major applications of filament tape and how choosing the right filament tape suppliers can enhance transformer performance, reliability, and longevity.

Transformers must endure heavy vibrations, thermal stress, and mechanical load during operation. Filament tape, reinforced with strong fiberglass filaments, offers exceptional tensile strength, making it ideal for reinforcing joints, connections, and support areas.

Real-world example: A leading European transformer manufacturer reported a 15% improvement in mechanical reliability after integrating industrial filament tape into key structural points.

By working with trusted filament tape suppliers, manufacturers can select tapes optimized for structural reinforcement, ensuring better alignment, durability, and safety.

Outdoor transformers face challenges like UV exposure, rain, extreme temperatures, and dust. Using weather-resistant filament tape to wrap and seal critical components creates an effective protective barrier.

Key advantages:

Protecting vulnerable spots with bi-filament or cross-woven filament tape can significantly extend service life, especially in tropical and desert regions.

A growing trend in industrial design is combining functionality with aesthetics. Colored filament tapes allow for visual differentiation between transformer units or branded installations without compromising performance.

Branding opportunities include:

Choosing colored options from specialized filament tape suppliers helps companies maintain consistency while offering high technical performance.

In fast-paced industrial environments, temporary solutions can prevent costly downtime. During scheduled maintenance, technicians often rely on industrial filament tape for quick fixes:

Case Insight: In a recent maintenance operation in Germany, technicians used filament tape to temporarily contain a minor insulation breakdown, allowing the transformer to operate safely for another six weeks until parts arrived.

Keeping industrial-grade filament tape on-site ensures rapid response capabilities and improves maintenance efficiency.

Compared to other specialty materials, the filament tape price remains competitive, offering an excellent balance of performance and affordability.

Benefits of bulk purchasing from reliable filament tape suppliers include:

Cost-effective strategies in material procurement directly impact transformer lifecycle costs and operational budgets.

Q1: Is filament tape heat resistant?

A1: Yes. High-quality filament tape withstands significant thermal stress, making it suitable for high-temperature transformer environments.

Q2: Can filament tape replace mechanical fasteners?

A2: In certain reinforcement applications, filament tape can supplement or temporarily replace fasteners, but it should not be a permanent substitute in high-load areas.

Q3: How to choose the right filament tape for transformers?

A3: Consider tensile strength, temperature resistance, environmental protection needs, and supplier reliability.

The role of filament electrical tape in power transformer design extends far beyond traditional insulation. By exploring new applications — from structural reinforcement to branding — engineers can unlock significant performance and cost benefits.

Partnering with experienced filament tape suppliers ensures access to high-quality, customizable options tailored to modern transformer demands. Embracing innovative uses of filament tape today means building a stronger, more reliable energy future.

Explore our industrial filament tape solutions here and upgrade your transformer designs today.